PRIVATE LABEL

A. Correia Malhas quality management system is focused on consistently meeting customer’s requirements and enhancing their satisfaction. It is therefore based on a wide set of inspection and control actions, covering all production steps and processes, from raw materials’ selection and sourcing up to the final product delivery.

RAW MATERIALS (YARNS) SOURCING

The high quality of our products is not only guaranteed by the control procedures throughout all production steps, but it is also given by the high quality of the raw materials we use for their production. We have developed strong and reliable partnerships with some of the best yarn suppliers in the market, thus assuring fast deliveries and competitive prices.

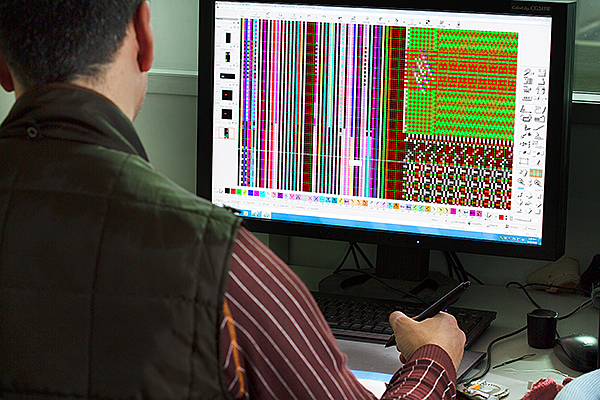

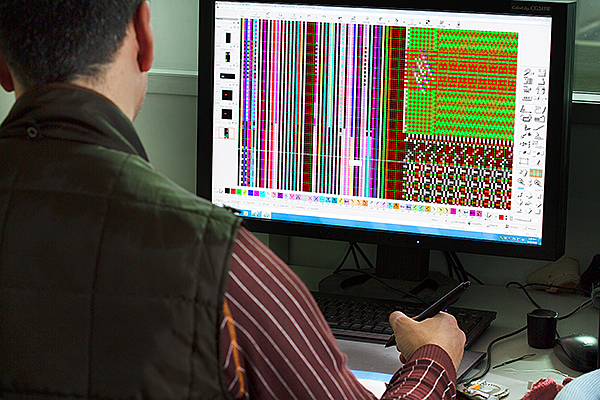

DESIGN SYSTEM

Our team of designers use Shima Seiky and Stoll software to produce the style’s designs and the knitting programs.

KNITTING

The factory is equipped with 120 knitting looms in gauges 3/5/7/10/12/14. Our knitting machines work around the clock, in a three-shift system.

WASHING

All the knitted components are washed and dried before being assembled.

ROLL PRESS

After washing, all the knitted components are pressed.

CUTTING

Each knitted component is cut down to its final size and measures.

ASSEMBLING

The perfect assembly of the knitting components is guaranteed by our professional and skilled operators.

LINKING

The linking process is carry out by highly skilled operators.

METAL DETECTION

All garments are submitted to metal detection control.

PRESSING

The pressing operation provides the garment an optimal look and touch.

END CONTROL AND PACKING

All garments are controlled a last time before being folded and packed.